Hot oil boiler

HOT OIL BOILER

Hot oil boilers are made in the form of coils and three assists for a capacity of 300,000 to 600,000 kilocalories kcal per hour per hour and a maximum working temperature of 320 ° C and at a pressure of 10 bar in both horizontal and vertical are made.

Designing and manufacturing according to ASME standards meeting the requirements of DIN 4754, IPS-M-AR 105 standards

All testing and inspection operations during the construction are done by the third and inspector approved by the technical inspection and quality inspection standard of Iran

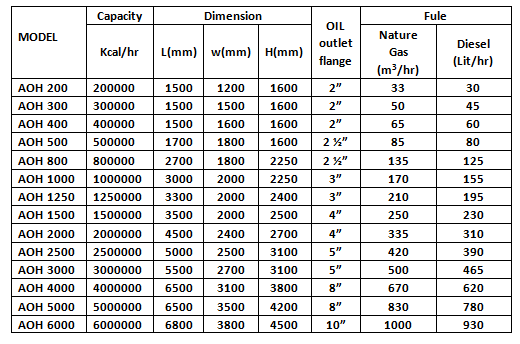

The capacity from 300,000 kilocalories per hour to 6,000,000 kcal per hour

Hot oil machine in both horizontal and vertical forms as a coil tube at three thermal passes design temperature 350 ° C and 320 ° C operating temperature allowed.

Has the Chamber of oil rotation at the end of the thermal that oil boiler will enter into the boiler.

Shell made of alloy steel 17mn4 (DIN17155) to a thickness of 10 mm that is arc welded by automatic welding machine

Ultrasonic testing of longitudinal and circumferential welds to 100%.

Shell inner surface will be covered by refractory mass of 1300 ° (NC 11-13) to a thickness of 50 mm.

All pipes used in coils are of Sch40, St 35.8 (DIN 17155) alloy connected to each other by arc welding and radiographic testing of welds will be performed.

Equipped with drop-down door that is embedded in the body and enables removing and moving of end chamber and coils completely by rails embedded in the Shell floor.

All welding electrodes used are of E7018, E6010 type brand BOHLER or GEKA used as pre-heated.

Isolation of body by compact wool-rock with a density of 100 KG/M3

Veneer of polished stainless steel with a thickness of 75/0 mm

Specifications: