Deaerator

DEAERATOR

It is a device for removing oxygen of water and preheating of water to enter the boiler.

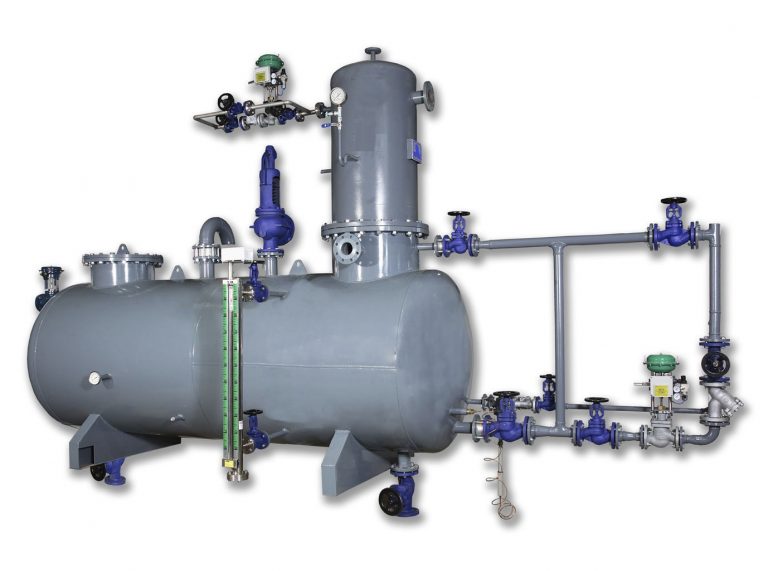

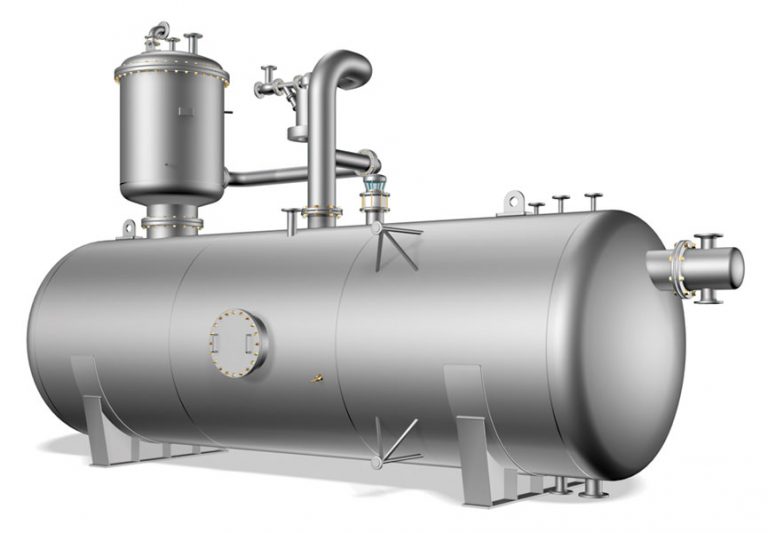

De-aerator is used to pre-heat the incoming water to the boiler and to remove dissolved oxygen and carbon dioxide gases. In the boilers, it is recommended that, to prevent thermal shock phenomenon, avoid adding water with low temperature into the boiler. This is because in addition to reducing efficiency and steaming capacity, boiler in intermittent contact with cold water and hot surfaces and heat transfer reduce the life of pipes and furnaces. Moreover, since dissolved oxygen in the water is always a corrosive agent for heat transfer surfaces in boilers, it is recommended that by increasing the temperature of the water entering the boiler, this oxygen be reduced. As the carbon dioxide gas in the water increases, PH of boiler water reduces and the environment finds acidic feature that is one of the factors accelerating corrosion in boilers. In order to reduce water insoluble gases, by increasing the water temperature, one can reduce solubility to an acceptable level. The solubility of gases in water is inversely related to temperature. As de-aerator water temperature is closer to 100 degrees Celsius, the amount of dissolved gases in the water becomes closer to 0 PPm. To increase the temperature of de-aerator water, steam produced in boilers is used. This means that one part of the steam of the boiler according to the capacity of the de-aerator, rate of return condensate, and feed water is replaced, and after pressure reduction enters the bottom turret into the de-aerator. Moreover, input water from condensate tank is poured from the nozzle turret top on trays of heat transfer and mass transfer inside the roof. Water pours from the top on the trays and steam moves bottom to up (reverse flow) in the tray mass transfer and heat transfer process is done. In simple terms, after passing water from the tray and its temperature rises, insoluble gases are reduced. In the body of the de-aerator tank, a preheater steam nozzle is considered that in emergency situations and times when the water temperature of de-aerator is dropped, by direct steam injection into the reservoir increased water temperature to an acceptable level. It is necessary that the de-aerator be installed at the proper height and distance calculated from the boiler pumps to prevent possible cavitation. De-aerator working pressure is considered at about 0.5 bars to have the ability to produce water of about 100 degrees Celsius.

Rules of pressurized de-aerator performance

If a fluid is at its saturation temperature, gas dissolution rate is almost zero. This is while the liquid must have very high turbulence or should boil to ensure complete removal of all the gas. This turbulence is achieved in the upper part (turret) of the de-aerator with spraying and turning into small droplets and surrounding these droplets with steam and the water loses its dissolved oxygen much easier. This incidence allocates a higher level relative to the mass of water allocated to it that makes the heat transfer from the steam to drop rapid and simplifies the separation of oxygen. These gases exit by excess steam from the boiler output at a temperature lower than the saturation temperature. The issue that the mixture of additional steam and gas at a temperature lower than the boiling point (saturation temperature) is under pressure helps us uses an output with thermostat controller so that de-aeration is done. Then the water on which separation operations is carried out overflows into the tank of de-aerator.

Water distribution in the de-aerator

Water entering the de-aerator should be divided into smallest droplets possible so that the surface in contact with air compared to the mass of water increases. It is important that the water temperature rises so that besides this level increase, gas withdrawal from the liquid is done at high speed inside the turret de-aerator. Grounding water in the de-aerator has different methods that have been mentioned below:

One of these methods is the contact of this water a number of perforated trays. In this method, water grounds with contact to a series of perforated trays and at the time is placed in contact with the steam and heat from the bottom. Another method is using spring nozzles that by applying a force upward and against the entrance force of the fluid and passing the fluid through their thin valves, they spray fluid. Of course, in choosing these methods, there are reasons to select or reject each. In a place that costs should also be considered, it is seen better. For example, in de-aerator with tray, the life of these devices can be up to 40 years, but in the case of spraying, this life is reduced to 20 years. However, the price of the one with tray is up to 25 percent more, the efficiency of the one with tray is much higher. The de-aerator with tray is usually used in plants, and spray is used in the rest of uses.