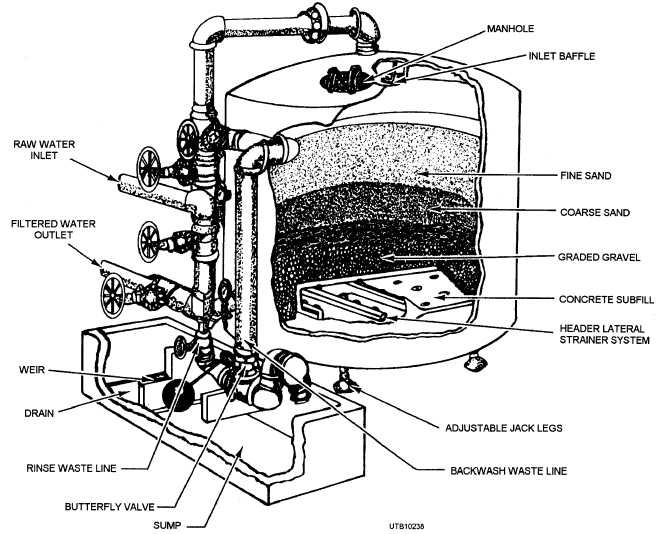

Inside sand filters, there should be four different layers of silica sand with uniformity coefficient of 35.1, fine-grained of special rocks and purity of over 95%.

Grade one silica from 5.0 mm to 5.1 mm in diameter

Grade two silica of 2 mm to 5.3 mm in diameter

Grade three silica of 4 mm to 8 mm in diameter

Grade four silica of 8 mm to 12 mm in diameter

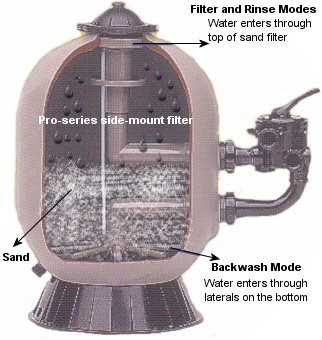

All silica spilled in sand filter in total will reach a height of one meter and this number does not depend on the capacity of the filter because after experiments done with sand filters, this has been proven. From a special height on, the material used in the filters are not capable of treating more water and a maximum height of 1.5 meters is considered, and by considering the filter bed filter and water distributor, the height of sand filters reaches a height of 1.5 meters. Sand with finer granularity provides more surface area and thus takes more water pollution. However, it needs more pumping energy for transmission of fluid. In any case, in the majority of pressure sand filters, grains of range 0.2 to 1.22 mm are used. Particles larger than 100 micrometers tend to close filtration pores. The larger grains of sand can overcome this problem. That is why the sand bed depths of about 0.6 to 1.5 meters are different depending on the application. Designing sand and grain filters shows that, they should work at a maximum flow rate of 10gpm/ft2. Using the power required and maximum discharge, the needed area can be calculated. The final point of designing is to make sure the liquid is properly flowing in the bed and no amount of fluid flow is deviated from the flow path.

When pressure of the two heads of sand filters is fixed at 0.8 – 0.6, it is the time to remove filter from service and to wash the beds with the entry of water in Back Wash form. Washing time depends on the amount of turbidity of input water. When filter piles up large amounts of soil, pressure drops and water cannot come out freely through the filter. Back wash sends water back so that by filtering trapped dust is led out. After back wash, pressure back increase to the pool is obvious and if the pressure gauge is installed on the filter, it can be seen that pressure is improved more than 0.5 bar.